Vibration Analysis

Vibration Monitoring is a key condition monitoring technology. It detects a large range of defects in rotating & reciprocating machinery, as well as providing diagnostic capability. Portable products allow you to measure many machines, ranging from a simple vibration meter to a multichannel diagnostic analyser. Online systems give you the peace of mind of continuous protection for your critical machinery. Abu Zaeem LLC technical team is expert in following,

- Portable Vibration Monitoring

- Online Vibration Monitoring

- Wireless Vibration Monitoring

- Operational Deflection Shapes (ODS)

- Phase Analysis

- Time Waveform Analysis

- Spectrum Analysis

- Coasting up/Run down test

- Bump Test

- Time Synchronous Averaging TSA

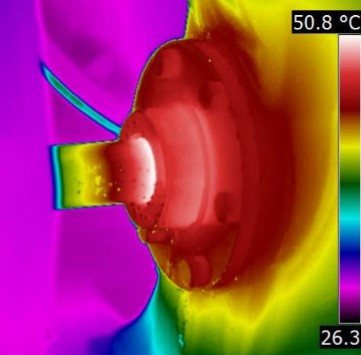

Infrared Thermography

Thermography is the process of using an infrared camera to look for abnormally hot or cold areas on a component operating under normal conditions. The main benefit of infrared thermography testing over the destructive testing techniques is that large areas can be scanned fast and with no need to be destroyed during testing. This results in major savings in time, people, work and machinery.

Fault Detection in Electrical Equipment

- Loose Connection

- Poor contacts,

- Overloading,

- Capacitor breakdowns

- Unbalanced loads

- Overheating

Fault Detection in Mechanical Equipment

- For Motors, pumps, compressors, fans blowers & gear, overheated bearings and excessive oil temperatures.

- Air leaks and clogged condenser tubes in refrigeration systems

- Broken and defective valves detection.

- Insulation breakdown

Ultrasonic Inspection:

Ultrasonic inspection is a commonly used method by using an array of multiple elements to scan over the whole specimen area. Acoustic emission (AE) is an established NDT method based on monitoring transient, elastic wave packages in a material, which accompany irreversible in its internal structure. The AE events are then detected by acoustic wave transducers attached to the specimen.

- Gas Leakage Detection

- Mechanical Faults

- Electrical Faults

- Very Slowly Rotating Machinery

- Steam Trap

- Steam Valve

Motor Current Signature Analysis (MCSA):

Motor current signature analysis is a technique that helps in determining the induction motor’s operating condition without disturbing production. Motor current signature analysis helps in detecting the following:

- Rotor bar damage

- Load issues

- Dynamic eccentricity

- Static eccentricity

AL Azaiba South , Muscat, Oman

Sun–Thus:8am – 5pm

News & Updates

The latest news, articles, and resources, sent straight to your inbox every month.